The Evolution of Cut-Resistant Technology in Ice Hockey Gear

In the fast-paced, high-contact world of ice hockey, player safety has always been a top priority. From the earliest days of the sport, players and equipment manufacturers alike have sought ways to minimize the risk of injuries, particularly those caused by cuts from sharp skate blades and sticks.

One of the most significant advancements in this regard has been the development of cut-resistant technology in ice hockey gear. In this article, we'll take a deep dive into the evolution of cut-resistant technology, exploring its roots, key milestones, and the impact it has had on player safety.

Early Days:

From Wool to Kevlar In the early days of ice hockey, players relied on simple, often inadequate forms of protection against cuts and abrasions. Wool socks and jerseys provided little defense against the sharp edges of skate blades, leaving players vulnerable to serious injuries. However, as the sport evolved and the need for better protection became apparent, manufacturers began experimenting with new materials and designs.

One of the first breakthroughs in cut-resistant technology came with the introduction of Kevlar, a synthetic fiber known for its exceptional strength and durability. Originally developed for use in ballistic vests, Kevlar soon found its way into ice hockey equipment, offering players a higher level of protection against cuts and lacerations. Early iterations of Kevlar-reinforced socks and jerseys paved the way for further advancements in cut-resistant gear.

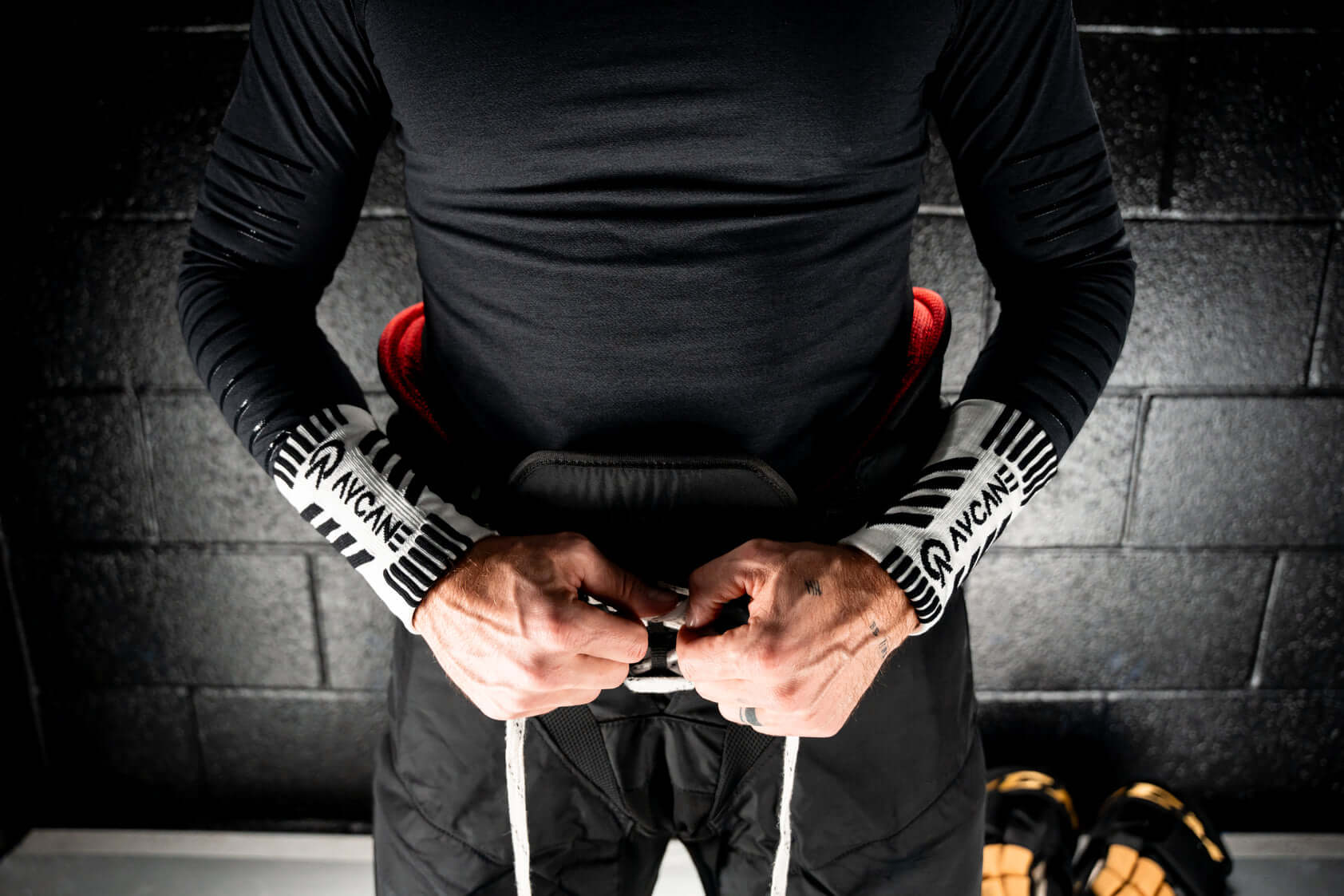

Advancements in Materials and Design As the demand for cut-resistant gear grew, so too did the need for more advanced materials and designs. Manufacturers began incorporating other high-performance fibers such as Dyneema and Spectra, which offered similar levels of protection to Kevlar but with added benefits such as increased flexibility and breathability. These materials were woven into the fabric of socks, base layers, and wrists guards, providing players with comprehensive coverage without sacrificing comfort or mobility.

In addition to improvements in materials, designers also began experimenting with new construction techniques to enhance the effectiveness of cut-resistant gear. Strategic placement of reinforced panels and seams helped to further minimize the risk of injury in vulnerable areas, such as the wrists and ankles. The result was a new generation of ice hockey equipment that offered unparalleled protection against cuts and abrasions while still allowing players to perform at their best.

The Role of Technology and Innovation In recent years, advancements in technology have played a significant role in driving further innovation in cut-resistant gear. The use of computer-aided design (CAD) software has enabled designers to create more intricate and precisely engineered gear, optimizing performance and protection without adding unnecessary bulk or weight. Additionally, advancements in manufacturing techniques such as 3D printing have opened up new possibilities for creating custom-fit gear tailored to the unique needs of individual players.

Furthermore, the integration of smart textiles and sensors into cut-resistant gear has provided an added layer of safety and functionality. These technologies can detect impacts and alert players, coaches, and medical staff to potential injuries in real-time, allowing for quicker response and treatment. In an era where player safety is more important than ever, these innovations are helping to raise the bar for what is possible in terms of protection on the ice.

Looking Ahead:

The Future of Cut-Resistant Gear As we look to the future, the evolution of cut-resistant technology in ice hockey gear shows no signs of slowing down. Continued advancements in materials, design, and technology promise to further enhance player safety and performance on the ice. From lightweight, breathable fabrics to intelligent, connected gear, the possibilities are endless.

Ultimately, the evolution of cut-resistant technology in ice hockey gear is a testament to the ongoing commitment of players, coaches, manufacturers, and innovators to prioritize safety above all else. By staying at the forefront of technology and embracing new ideas and approaches, we can ensure that the next generation of ice hockey players will have the tools they need to compete confidently and safely, both now and in the years to come.

Conclusion:

The journey from wool socks to high-tech, cut-resistant gear has been one of constant innovation and improvement. As we reflect on the evolution of cut-resistant technology in ice hockey gear, it's clear that we've come a long way from the early days of the sport. With each new advancement, we move closer to our ultimate goal of creating a safer, more enjoyable playing experience for athletes of all ages and skill levels. And as technology continues to evolve, so too will our approach to protecting the players who make the game great.